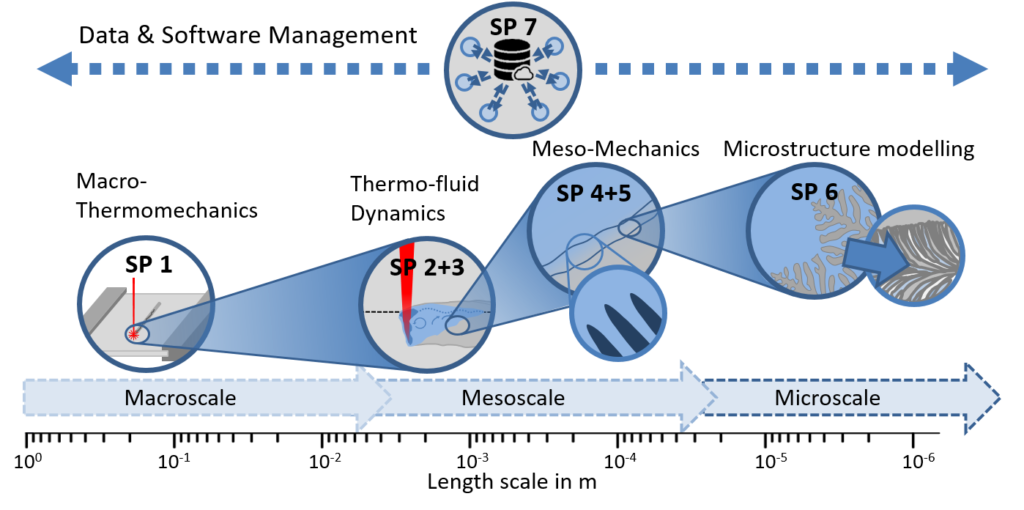

To achieve the challenging objectives of the research unit, the project is divided into seven scientific sub-projects that are closely related and work closely together. They are assigned according to the simulated scales and analyse the laser beam welding process in parallel at all levels – from the macro scale to the micro scale.

In sub-project 1 (SP1), a thermo-mechanical research of laser beam welding is carried out at the component level respectively macro scale. In sub-project 2 (SP2) and sub-project 3 (SP3) a thermo-fluid dynamic and massively parallel simulation of the welding process on mesoscale is developed. Sub-project 4 (SP4) and sub-project 5 (SP5) design a multi-scale thermoplastic simulation of the solidification zone. Subproject 6 (SP6) considers solidification in the weld seam using a microstructure simulation. The simulations are supplemented by experimental work that is being carried out in SP1 and SP2. In order to be able to manage and exchange the resulting large amounts of data and software in the long term, sub-project 7 (SP7) was developed to implement data and software management.

The superordinate objectives of the research unit results in a strongly interrelated structure of the sub-projects. SP2 and SP3 as well as SP4 and SP5 work together as tandem projects on a high-performance simulation framework. SP1 and SP2 work closely together as part of the planned experiments, especially in the area of temperature measurements. The simulations of macro-thermomechanics, thermo-fluid dynamics, meso-mechanics and microstructure development exchange different parameters among each other. Beyond the tandem projects, sub-projects work on common issues or provide infrastructure and specifications.