As a flexible and contactless joining technology, laser beam welding has increasingly gained importance. Processing of alloys with large melting range poses a challenge due to their solidification crack tendency. Despite the high industrial relevance, current approaches are only addressing single aspects of the problem. Therefore, researchers have been working within the research unit FOR5134 in seven sub-projects since 2021 on developing a predictive, efficient and highly scalable multi-scale and multi-physical simulation framework in order to develop a quantitative process understanding on the mechanisms of solidification crack formation. This website offers you an overview of the objectives, the structure and the researchers involved.

Scientific motivation

In the course of the increasing degree of automation in industry, laser beam welding has gained considerable importance. One of the biggest challenges are solidification cracks that occur in the weld seam during welding. A large number of experimental and simulative research projects have been dedicated to this topic for several years. Numerous, predominantly qualitative theories currently exist in parallel, which pursue metallurgical, strain or stress-oriented approaches. So far, it has not been possible to develop a clear and quantitative description of the model through experiments. However, a quantitative understanding of the mechanisms by which solidification cracks develop is essential for improving the laser beam welding process.

Research objectives

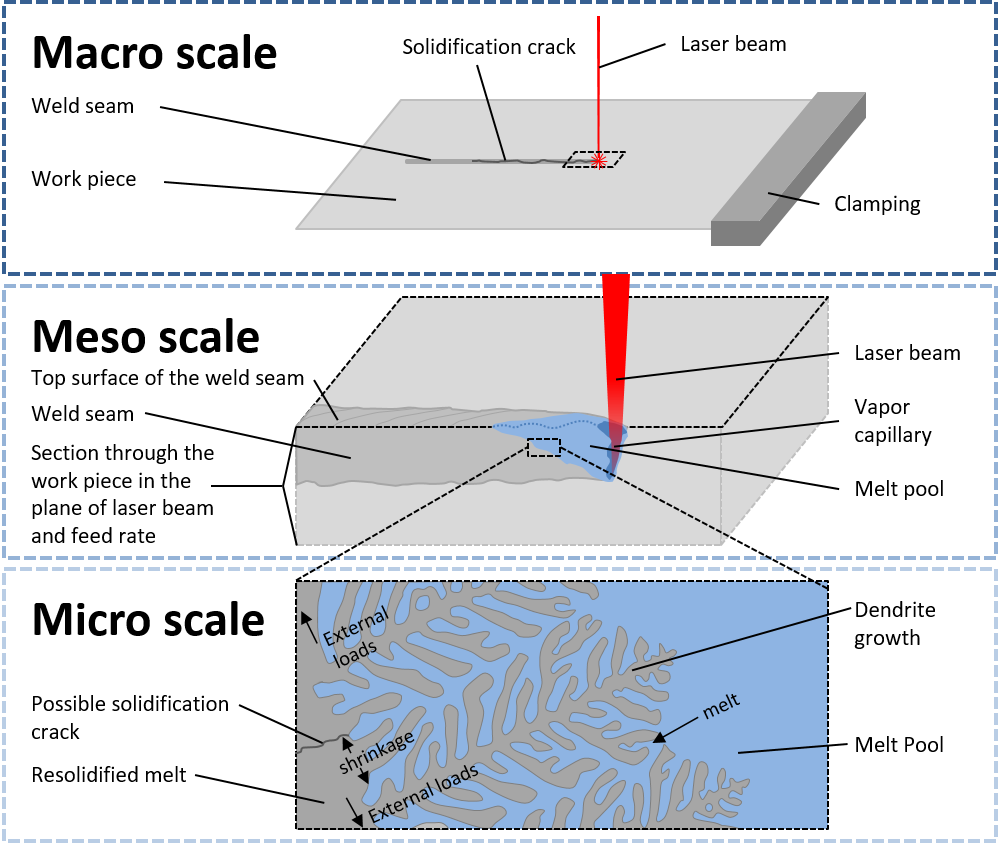

Our main objective is to develop a process understanding on the formation of solidification cracks and their correlation to process parameters. For this purpose, the relevant phenomena from macro to meso and down to the micro scale are to be mapped in a quantitative process model. With this model, mechanisms of solidification crack formation should be identified and correlated with process parameters in order to enable a prediction of solidification crack probabilities.

Interdisciplinary collaboration

Our research requires expertise from the fields of mechanical engineering, production engineering, materials science and engineering, mathematics and computer science. For the first time, the research unit is considering the problem of the formation of solidification cracks in laser beam welding on a cross-scale and multi-physical basis and assumes that the interdisciplinary research approach will lead to new scientific awareness.

Visit us on our LinkedIn page (www.linkedin.com/company/for5134) to stay up to date and get more information about the research group.